Delta-8 THC Study: Nanoemulsions vs. Oil Solution – Which Offers Superior Absorption?

A new pharmacokinetic Delta-8 THC study by Industrial Sonomechanics shows groundbreaking results in the cannabis space.

Nanokinetics® recently interviewed Dr. Alexey Peshkovsky, President and Chief Scientific Officer of Industrial Sonomechanics (ISM) regarding a recent preclinical pharmacokinetic study that ISM conducted in collaboration with Verdient Technologies. The study compares two types of nanoemulsions (liquid and powdered) with an MCT oil solution that mimics traditional edibles and gummies. Dr. Alexey Peshkovsky provides insights into this study, discussing the results in terms of ‘bioavailability’ and ‘absorption rates’ of cannabinoids.

This study is highly relevant to Nanokinetics, as we offer water-soluble nano-ingredients, including formulations for kratom, kava, CBD, and THC, designed to meet our customers’ specific requirements.

Links to a peer-reviewed journal publication and a video discussion on this subject are included at the end.

Q1. Can you provide a brief overview of your background and expertise in the field?

A.P. I’m the Co-Founder, President, and Chief Scientific Officer of Industrial Sonomechanics (ISM). I hold a B.A. in Chemistry from the University of Pennsylvania and an M.S. and Ph.D. in Physical Chemistry from Columbia University.

In 2006, my father and I founded Industrial Sonomechanics to commercialize our invention of the Barbell Horn® Ultrasonic Technology that allows increasing the sizes of ultrasonic processors to production scale without having to reduce the ultrasonic amplitudes and cavitation intensities they are able to generate – an essential condition for producing high-quality nano-formulations and many other processes. Currently, our Barbell Horn®-based ultrasonic equipment is sold worldwide, helping thousands of companies working with a wide range of industrial and research applications.

At our R&D facilities, we conduct many research studies involving various processes within the ultrasonic liquid processing field. One of the most important application areas we work with is the delivery of poorly water-soluble biologically active compounds into the human bloodstream via the oral/digestive route. This is a broad field that spans several industries, including pharmaceutical, nutraceutical and cannabis. It typically involves figuring out how to formulate these compounds as liquid or powdered nanoemulsions or other nano-formulation types and how to subsequently transfer these processes to production scale, which is what we did during this Δ8-THC study as well.

Q2. What motivated you to pursue research specifically on Δ8-THC nanoemulsions? What were the reasons behind your decision to conduct this study?

A.P. Industrial Sonomechanics organized, produced the materials for and sponsored this Δ8-THC pre-clinical trial, and Dr. Michael Tagen – a pharmacokinetics specialist from Verdient Science – assisted us with the study design and results interpretation. Our decision to conduct this study was driven by a combination of factors.

We recognized the significant scientific potential for innovation within the cannabis industry. As an active R&D company, Industrial Sonomechanics explores processes related to our ultrasonic technology, including formulation development and production of bioactive nanoemulsions.

Nanoemulsions have shown significant promise for improving the delivery of various bioactive compounds across industries such as nutraceutical, pharmaceutical, and food & beverage, and cannabis. With the increasing popularity of Δ8-THC within the cannabis industry and the lack of prior studies, we saw an intriguing opportunity for exploration.

We specifically wanted to study nanoemulsions made with our ultrasonic technology in combination with two of our all-in-one excipient blends – NanoStabilizer®-LT and NanoStabilizer®-LSO, with the goal of providing valuable data and insights to benefit both our clients (manufacturers of finished nanoemulsion products) and consumers in the cannabis market.

It was also an opportunity to address a significant knowledge gap. There has been widespread misunderstanding regarding the concept of bioavailability and its relevance to cannabis consumers. It was essential for us to define what bioavailability is and what it is not, as claims of “greater bioavailability” can often be misinterpreted or used without meaningful context for consumers’ experiences.

Q3. What were the primary findings of this Delta-8 THC study?

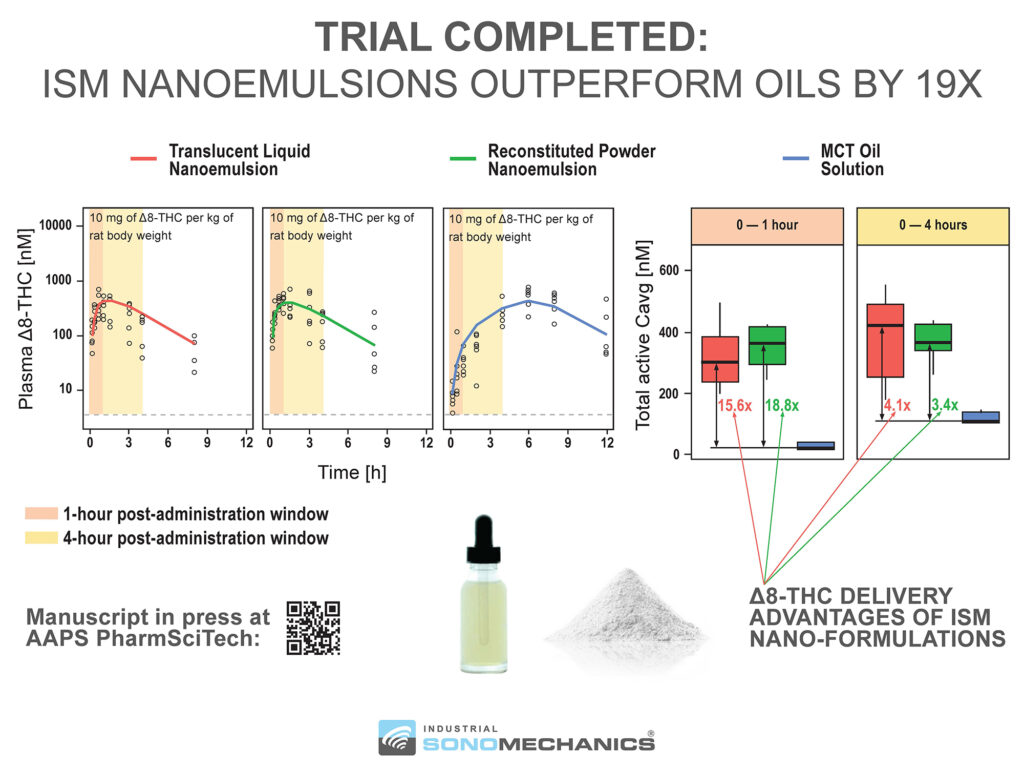

A.P. The results demonstrated considerable advantages of nanoemulsions produced with ISM’s ultrasonic equipment and NanoStabilizers®. The nanoemulsions very significantly outperformed MCT oil solutions (which mimic traditional edibles, gummies and tinctures), providing up to almost 19x greater absorption of Δ8-THC during the first hour after administration. The nanoemulsions featured in this study were:

- A liquid translucent nanoemulsion, made with NanoStabilizer-LT, having the median droplet size of 27 nm. NanoStabilizer-LT is a formulation aid product that we launched in 2016. It is an all-in-one excipient pre-mix that is offered to manufacturers in the cannabis space to enable them to produce their own water-soluble translucent nanoemulsion liquids with very small droplet sizes.

- A “powdered nanoemulsion”, made with NanoStabilizer-LSO, having the median droplet size of 168 nm. NanoStabilizer-LSO is another all-in-one formulation aid we offer to our customers who are looking to produce water-soluble nanoemulsion powders.

Both nanoemulsions enabled a much more rapid onset time and a much shorter time maximum concentration in the bloodstream (~5 min and < 1 hr, respectively) than the MCT oil solution (~ 1 hr and 6 hrs, respectively). The translucent liquid and powdered Δ8-THC nanoemulsions displayed similar properties to each other.

The findings are detailed in our recent paper published by AAPS PharmSciTech, an official journal of The American Association of Pharmaceutical Scientists.

Q4. From the perspective of cannabis product manufacturers, how significant are these findings?

A.P. Our study results have significant implications for cannabis product manufacturers, offering them a substantial competitive edge in the marketplace. By adopting our nano-emulsification technology for the delivery of Δ8-THC and other cannabinoids, manufacturers can differentiate their products through offering faster onset times and greater absorption within the therapeutic window of interest. This will attract consumers seeking more efficient and consistent experiences with cannabis consumption.

The use of nanoemulsions will also allow manufacturers to overcome challenges associated with the aqueous solubility of Δ8-THC and other cannabinoids, and enable them to produce water-compatible cannabis products, such as beverages, tablets, instant powder mixes, and many others.

The adoption of nanoemulsion technology aligns with the overall trend in the cannabis industry towards innovation and product diversification. Manufacturers who leverage our pre-clinical trial findings and implement nano-emulsified Δ8-THC-infused products will be able to position themselves as leaders in the industry, catering to evolving consumer preferences and demand for better consumption methods.

Q5. Can you explain the process of creating the liquid and powdered nano-formulations?

A.P. Creating both liquid and powdered nano-formulations involves a straightforward process that leverages our NanoStabilizer products and turn-key ultrasonic equipment to achieve optimal results. We have enabled thousands of companies to start producing these products right away, without the requirement to have scientists or engineers on staff.

To produce liquid translucent nanoemulsions, our clients can simply follow the NanoStabilizer-LT User Guide (SOPs) that corresponds to their ultrasonic processor model and configuration. The guides are available on our Knowledge Hub webpage.The procedures for making nanoemulsions with different cannabinoids (Δ8-THC, CBD, Δ9-THC, CBN, CBG, etc.) and cannabis extract and isolate types are identical. These nanoemulsions are instantly water-soluble, and can be readily infused into a beverage or another water-based product, without changing its visual appearance.

As for powdered nanoemulsions, the process follows a similar trajectory using NanoStabilizer-LSO (the corresponding guides are also available on our Knowledge Hub webpage), but with an additional drying step required to convert the liquid nanoemulsion into the powdered form. Water-soluble nanoemulsion powders reconstitute back into liquid nanoemulsions once infused into a water-based product. The powders can also be used in the form of quick-disintegrating/chewable tablets, effervescent tablets or as part of fast-acting gummies, instant powder sachets (coffee, vitamins, proteins, etc.) as well as many others.

Q6. Is it possible to produce nanoemulsions by using generic surfactants and conventional ultrasonic equipment?

A.P. The ultrasonic production of high-quality nanoemulsions at scale involves two essential components:

- Optimized formulation

- Scalable high-amplitude ultrasonic equipment

The ultrasonic equipment used for the production is also extremely important. Conventional (not based on Barbell Horn® Ultrasonic Technology) ultrasonic processors cannot output high amplitudes on a production scale – a factor many overlook when making comparisons and purchasing decisions. Investing in a low-amplitude, low-intensity sonicator can lead to subpar results. High amplitudes are essential for generating the intense cavitation necessary to reduce the sizes of the bioactive-containing oil droplets down to the lower nanometer range, resulting in high-quality, stable nanoemulsions. Without such high-amplitude equipment, achieving the desired droplet size and stability is not possible, leading to inferior product quality and performance.

Q7. How does the experience of consuming a fast-acting, nano-emulsified liquid or powdered cannabis product compare to that with traditional oil tinctures or oil-infused edibles?

The formulation plays a crucial role in the process and resulting product quality. It determines how small the active ingredient-containing droplets can become during the production process and how stable they will be in the product after the process is finished. The effectiveness of the finished product is, in turn, largely determined by how small the nano-droplets are. In addition, since the formulation components (surfactants, carrier oils, etc.) remain in the finished product, it is important to ensure that they are food-grade and, preferably, natural, organic, and tasteless. Not all surfactants are suitable for creating high-quality nanoemulsions, as most are harsh, soapy and/or bitter, and synthetic. Additionally, the ratio of all ingredients in a formulation is critical, as small deviations from the optimized proportions lead to drastic increases in the droplet size, resulting in losses in effectiveness and stability of the finished product. Our NanoStabilizers are specifically designed to achieve the smallest possible nanoemulsion droplet sizes, are completely tasteless, and comprise food-grade components that are either derived from natural sources (LT) or are all-natural and organic (LSO). With these pre-mixed all-in-one formulations, no further development is required – they are ready to be used by anyone, regardless of whether or not the user has any scientific or engineering background.

A.P. Consuming a fast-acting, nanoemulsion-infused cannabis product offers consumers a significantly different experience.

For medical patients, especially those seeking quick symptom relief, the almost immediate onset of therapeutic effects can be crucial. Waiting hours for relief, as is often the case with traditional oil-based products, is not practical. Imagine having an anxiety attack and needing relief quickly; waiting for a medication to take effect after several hours is far from ideal. On the other hand, if one is looking to alleviate chronic conditions, an oil-based delivery system can be appropriate.

For recreational cannabis consumers, the desire for immediate effects is also prevalent. Whether socializing at a party or unwinding after a long day, waiting for hours for the cannabis effects to kick in can destroy the experience. It is also not uncommon for consumers to become frustrated and take an additional dose after waiting for over an hour for the desired effects, only to have the terrible experience of being overdosed hours later when both doses begin to act simultaneously. On the other hand, since the timing of action associated with nano-emulsified cannabis products is similar to that of alcohol, recreational consumers can enjoy a familiar, predictable, reproducible and safe experience.

While many choose to smoke or vape cannabis for quick effect, it’s known that doing so can impact lung health and produce odors and second-hand exposure. Having a cannabis nanoemulsion-infused drink or edible can provide a similarly rapid effect without the harsh impact on the lungs.

Video: Nanoemulsions vs. Oil Solution, Discussion with Alexey Peshkovsky and Ini Afia

Peer-Reviewed Publication: Pharmacokinetics of Two Nanoemulsion Formulations of Δ8‑THC

Have questions? Want to produce your own water-soluble liquid or powdered nanoemulsions? Contact Industrial Sonomechanics at 1.786.233.9255 or co*****@so***********.com.

A division of Industrial Sonomechanics®. Trademarks and registered trademarks are owned by Industrial Sonomechanics, LLC.